4Company dynamics

The principle of the release paper is mainly based on the special coating on its surface, that is, the release agent. This release agent is a polymer chemical substance, when the object is in contact with the release paper, it will be adsorbed on the surface of the release agent and a weak chemical adsorption reaction will occur. This reaction causes a layer of electrostatic field to form on the surface of the object, thus creating an isolation layer, while the surface of the release agent is rough and can form tiny bumps that prevent the object from continuing to contact the surface and achieve separation.

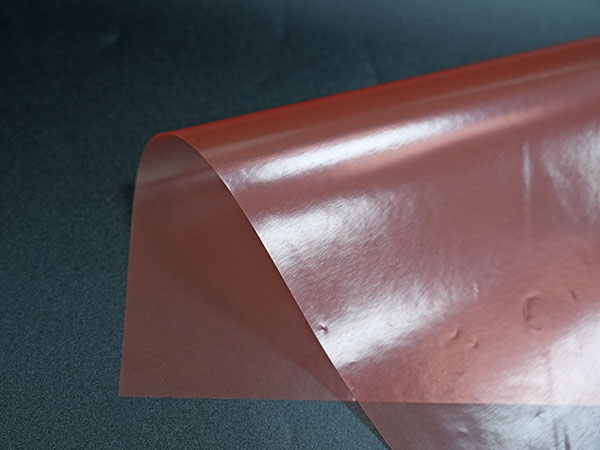

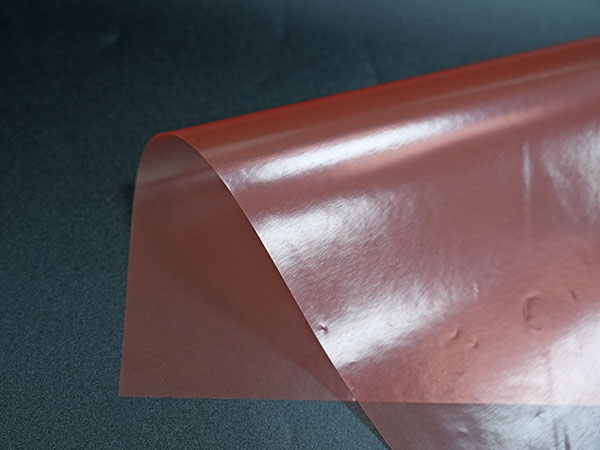

The structure of the release paper is usually composed of three layers: the base paper, the film and the silicone oil. The backing paper is usually ordinary paper, and the coating is to ensure that the release agent does not penetrate into the inside of the paper, usually using polyethylene (PE) particles for coating. Silicone oil is applied to the coating surface to provide an anti-stick effect. The classification of release paper can be classified according to whether there is plastic release paper and non-plastic release paper, and can also be classified into silicone release paper and non-silicon release paper according to release agent.

Production process of release paper:

Preparation: Prepare the raw materials, including base paper, glue, paint, etc.

Gluing: Glue is applied to the base paper to increase its bonding properties.

Bonding: The base paper and release material are bonded together to form release paper.

Drying: By drying the release paper at high temperature, so that it is completely dry and firmly bonded.

Cooling: Cooling the release paper to maintain its stability and performance.

Slitting: slitting the release paper as required to adapt to different use scenarios.

Packaging: The release paper is packaged to protect its performance and service life.

The main purpose of release paper is to provide an isolating layer when in contact with sticky materials to prevent sticky materials from adhering to the substrate. For example, release paper is widely used in electronic products , automobile foam , printing, food, medical and other industries. Especially in the production and use of adhesive tape , the release paper plays a key role in ensuring that the tape can be removed from the release paper.