4Company dynamics

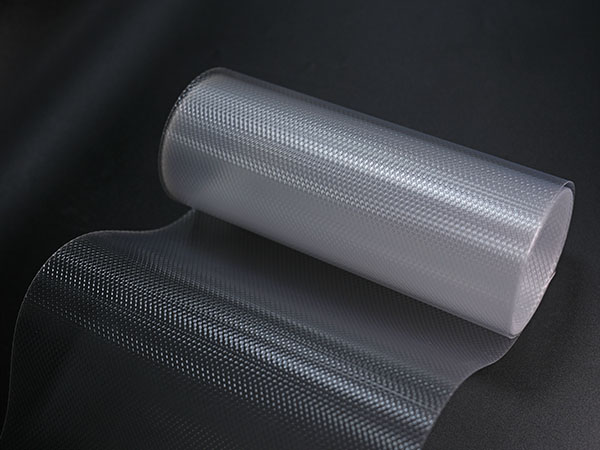

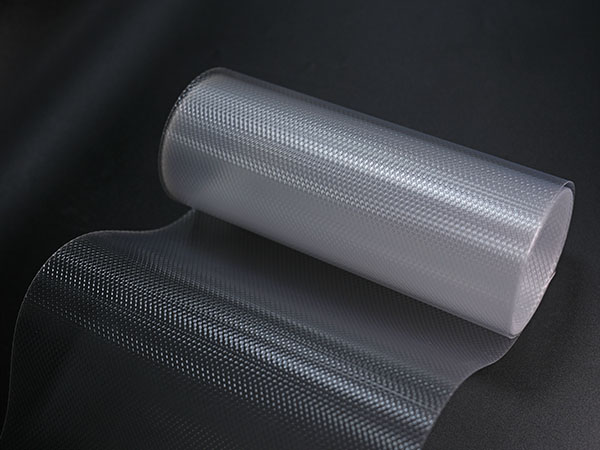

Mesh release membrane is a kind of polymer material, which is prepared by the combination of high molecular weight polyvinyl alcohol (PVA) and meshing agent. The toughness and tensile strength of membrane materials can be enhanced by adding meshing agent. The preparation of mesh release film mainly relies on release technology, that is, by coating a layer of release agent on the surface of the material to separate it from the coated material, so as to achieve the purpose of membrane material separation.

Production technology of mesh release film

1. Material preparation

The primary condition for preparing mesh release film is to ensure the quality and stability of raw materials, and the selected materials must meet national standards. Add PVA particles into a uniform hot water, dissolve into a yellow transparent liquid, and fully mix with the mesh agent.

2. Preparation of membrane

The mixed material is poured into the rectangular mold, and under the action of the temperature controller, the material is fully cooled and solidified, and then the surface of the film is covered with the release agent. When the release agent is dry, lift the top of the mold and gently pry the film away from the top of the mold with a scraper to get the mesh release film.

3. Film performance test

The prepared mesh release film needs to be tested for its thickness, toughness, tensile strength, moisture permeability and other performance indicators. Only meet the user requirements of the performance index, can be put into production.

Mesh release film is a kind of polymer material with a wide range of uses, which can be used in packaging, medical treatment, construction and other fields. With the function of air permeability, water resistance and seepage resistance, it is widely used in the construction industry in the field of roof waterproof, basement moisture proof and floor sound insulation. In the medical industry, mesh release membrane is mainly used for the preparation of disposable medical supplies, such as surgical sets, masks and so on. In addition, it can also be used for packaging and protection of electronic components.