4FAQ

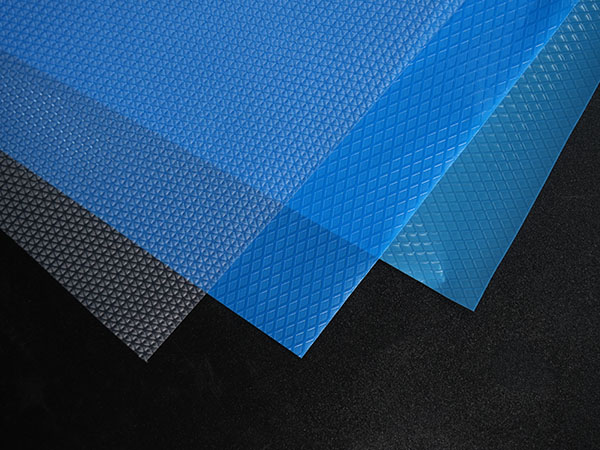

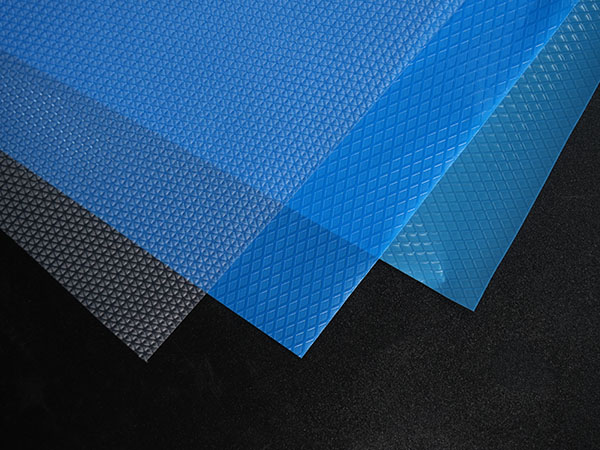

PE release film and PE protective film are made of PE material, so many friends do not know the difference. Although they are made of the same raw materials, they can be distinguished by their use.

First, distinguish PE release film from PE protective film in terms of use

PE protective film is used as the surface of electronic products for initial and factory protection, PE release film is used for the protection of raw materials and disposable consumables in the process.

The biggest advantage of PE protective film is that the protected products are not polluted, corroded, scratched in the process of production, processing, transportation, storage and use, and protect the original smooth and shiny surface, thereby improving the quality of products and market competitiveness.

PE release film is the world's most widely used polymer material, made of ethylene polymerization, PE release film is divided into high density polyethylene, medium density polyethylene and low density polyethylene. Low density polyethylene is soft and multi-purpose high pressure polymerization; High density polyethylene has the characteristics of rigidity, hardness and mechanical strength, and is used in low pressure polymerization.

High-density polyethylene can be used as containers, pipes, and high-frequency electrical insulation materials for radar and television. Low density (high pressure) polyethylene is often used in large quantities. Polyethylene is waxy and has a waxy smoothness. When not dyed, low density polyethylene is transparent, while high density polyethylene is opaque. Polyethylene is a high polymeric chain connected by repeated -CH2- units through the addition reaction and polymerization reaction of ethylene (CH2=CH2). The properties of polyethylene depend on how it is polymerized; High density polyethylene (HDPE) was synthesized by Ziegler-Natta polymerization under medium pressure (15-30 atmospheres) of organic compounds.

The polyethylene molecule polymerized under this condition is linear, and the molecular chain is very long, and the molecular weight is up to hundreds of thousands of thousands. If it is under high pressure (100-300MPa), high temperature (190-210C), peroxide-catalyzed free radical polymerization, the production is low density polyethylene (LDPE), which is branched structure.

In addition, PE release film is coated with release agent, it is not easy to be bonded, sticky objects can not be bonded on the above, mainly used for double-sided adhesive isolation, as well as label paper, etc., and PE protective film coated with low-viscosity adhesive water, although low viscosity but still have a certain viscosity, generally used to protect the surface of the material.